Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

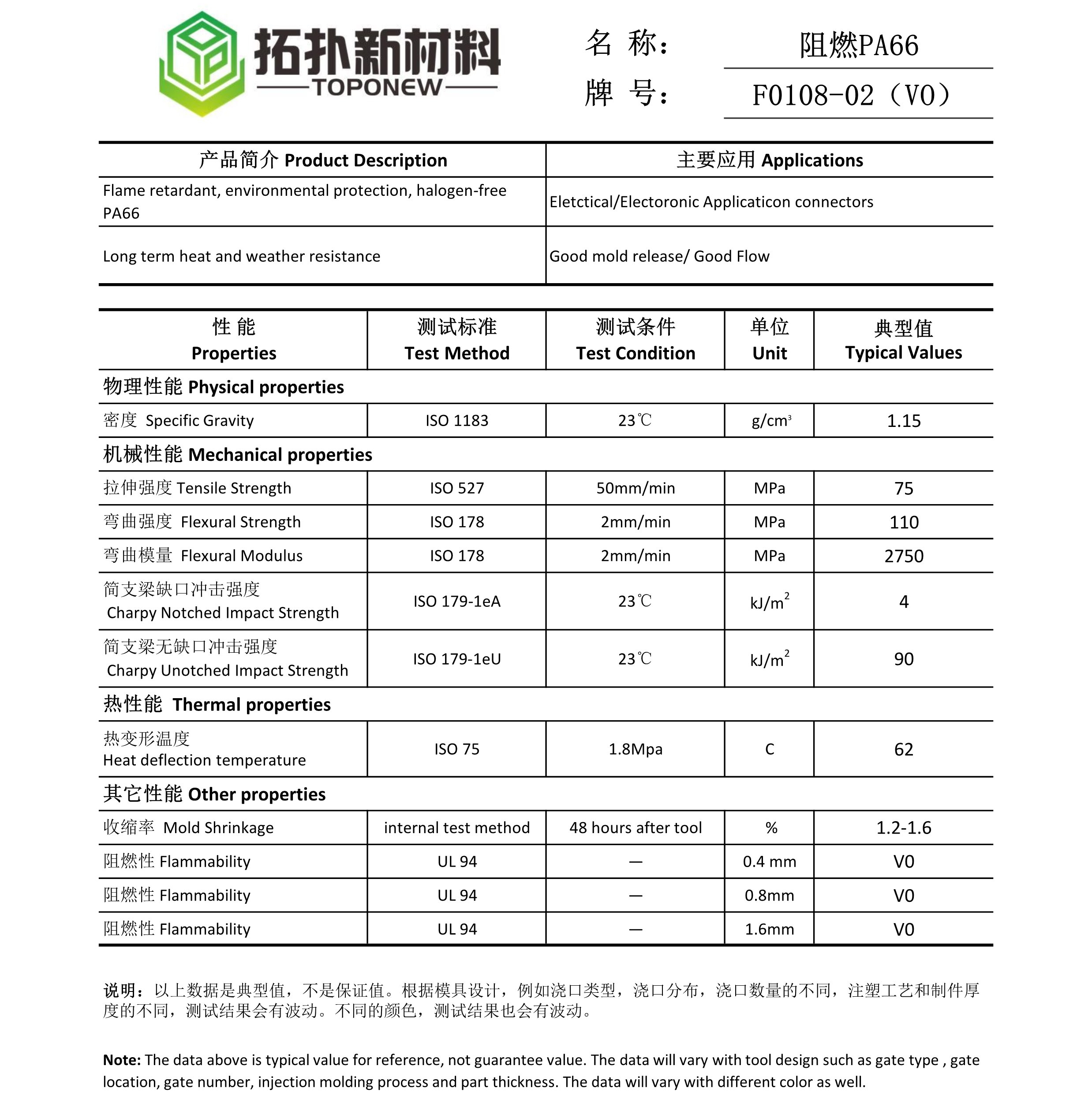

PA66 F0108-02(V0)

UL94 1.6mm V0

Halogen free

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

PA66 GF20/ PA66 GF30/ PA66 GF35/ PA66 GF40/ PA66 GF50

Introducing PA66 F0108-02(V0) – a premium-grade polyamide nylon 6.6 material known for its outstanding properties. This UL94 1.6mm V0 and halogen-free material offers superior flame resistance, making it an excellent choice for applications requiring high safety standards. With excellent mechanical and thermal properties, PA66 F0108-02(V0) ensures reliability and durability in diverse industries.

PA66 granules PA66 UL94 V0, also known as polyamide 66 granules, are thermoplastic resins known for their exceptional properties and versatile applications.

Properties of PA66

PA66 granules exhibit excellent mechanical strength and toughness. They have high tensile strength, which makes them resilient under different types of stress. This property makes PA66 granules suitable for applications that require robust and durable materials.

PA66 granules also possess good heat resistance and dimensional stability. They can withstand high operating temperatures without significant deformation, making them suitable for applications in hot environments. Additionally, PA66 granules exhibit good resistance to chemicals, oils, and solvents, further expanding their usability.

Applications of PA66

One of the prominent applications of PA66 granules is in the automotive industry. They are used to manufacture various components like engine covers, fuel systems, electrical connectors, and interior parts. The excellent mechanical properties of PA66 granules ensure optimal performance and reliability in the demanding automotive environment.

PA66 granules are also extensively utilized in electrical and electronics applications. They are employed in the production of connectors, cable ties, circuit board components, and insulators due to their superior electrical properties and resistance to high voltages.

Furthermore, PA66 granules find application in consumer goods such as sports equipment, household appliances, and packaging. Their desirable combination of strength, toughness, and chemical resistance contributes to the durability and functionality of these products.

In summary, PA66 granules are versatile thermoplastic resins with exceptional mechanical and thermal properties. Their application spans across industries, including automotive, electrical and electronics, and consumer goods, where reliable performance and durability are paramount.

Q & A

1. Comparison of Nylon 6 and Nylon 66

Nylon 6 and nylon 66 are two widely used types of polyamide materials with distinct characteristics.

Nylon 6, also known as polyamide 6 or PA6, is a versatile and cost-effective thermoplastic. It has good mechanical strength, impact resistance, and abrasion resistance. Nylon 6 exhibits excellent flexibility and toughness, making it ideal for applications such as textile fibers, carpets, and automotive components. It also has a lower melting point compared to nylon 66.

On the other hand, Nylon 66, also known as Polyamide 66 or PA66, offers superior mechanical properties and enhanced heat resistance. It has a higher melting point, which allows it to withstand higher temperatures without compromising its strength. Nylon 66 is commonly used in applications that require higher stiffness, strength, and dimensional stability. It is often used in manufacturing electrical connectors, gears, bearings, and mechanical components.

Overall, Nylon 6 is more cost-effective and has better flexibility, while Nylon 66 offers greater strength and dimensional stability. The choice between the two depends on the specific requirements of the application, including factors such as temperature, mechanical stress, and cost considerations.

Download

-

PA66 F0108-02(V0).pdf

Download PA66 F0108-02(V0).pdf